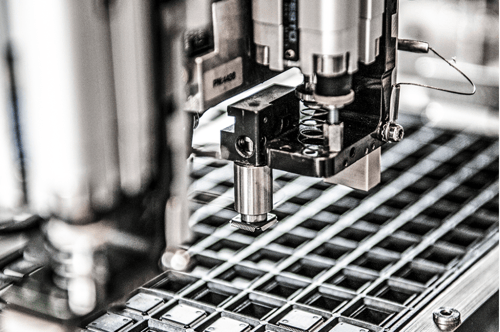

Semiconductor Production

A strong experience in producing semiconductors,

rooted in long history

Built over decades of experience producing and shipping 1 billion of semiconductor units, Presto Engineering operates a global, flexible, and dedicated supply chain system, allowing to secure its customers with capacity of over 50 million units per year.

Our on-staff team provides the following skillset to your business:

We consolidated all production-related functions into integrated teams of experts who are focused on getting your product to your customers or your internal operations as seamlessly as possible.

Local supervision by our experts

We operate five complete test floors, including two in Asia where your production will be supervised on-site by our resident personnel (both in Bangkok, Thailand and in Kaohsiung, Taiwan). We deploy, not only advanced automated test equipment (ATE) capacity, but also complete lines of wafer backend processing (back lapping, back grinding/thinning and dicing) and finishing (visual inspection, packing, tape & rill).

Most of our floors are secured (EAL 6 certified) and operated from our own, local IT systems, interconnected to a dedicated, secure network.

Strong relationships established with major foundries, OSATs and EMS partners

Our local partners provide packaging/assembly operations so we can process lots under the same roof, from probe test to wafer backend, assembly, final test, and finishing. Our backend operations are integrated into our OCEAN-based global supply chain B2B system, including MES integration and web-based WIP tracking―providing you with web-based access to the production-related reports you need.

We leverage our Hong Kong-based warehouse for efficient and cost-effective world-wide logistics as well as facilitated access to Asian EMS or end-markets.

From design to test and qualification to production.

Additionally, we have internal expertise sustaining your product’s ongoing production, yield, and quality, including:

-

Quality engineers: RMA process, customer interaction, G8D management

-

Product engineers: yield trend management, interface with design, product ownership

-

Device engineers: yield analysis, foundries interfacing, PCR management, corrective actions

-

Failure Analysis engineers: RMA analysis, reporting, root cause analysis, field returns (ppm)

-

Test engineers: test coverage - escape resolution, test time reduction

ASIC Design Solutions

ASIC Design Solutions

Customizable Silicon Platforms

Customizable Silicon Platforms

Semiconductor Manufacturing

Semiconductor Manufacturing

Test Services

Test Services